What is PP Homopolymerization and Copolymerization?

- Postdate: 2023-02-24

- From: qibochem.com

-

What is PP Homopolymerization and Copolymerization?

- Postdate: 2023-02-24

- Form: qibochem.com

-

Homopolymerization refers to the polymerization reaction carried out by an organic monomer.Copolymerization refers to the reaction in which two or more compounds are polymerized into one substance under certain conditions.

Classified according to international standards, polypropylene (PP) is divided into homopolypropylene (PP-H), random copolymer polypropylene (PP-R), block copolymer polypropylene (PP-B).

1 Homopolypropylene (PP-H)

1.1 It is polymerized from a single propylene monomer, and ethylene monomer is not included in the molecular chain, so the regularity of the molecular chain and the crystallinity of the material are very high, but the impact performance is poor.In order to improve the brittleness of PP-H, some raw material suppliers also adopt the method of blending and modifying polyethylene and ethylene-propylene rubber to improve the toughness of the material, but it cannot fundamentally solve the long-term heat resistance and stability of PP-H.

1.2 Advantages: good strength.

1.3 Disadvantages: poor impact resistance (brittle), poor toughness, poor dimensional stability, easy aging, poor long-term heat resistance and stability.

1.4 Uses: extrusion blowing grade, flat yarn grade, injection molding grade, fiber grade, blown film grade. It can be used for packing belts, bottle blowing bottles, brushes, ropes, woven bags, toys, file folders, electrical appliances, household items, microwave lunch boxes, storage boxes, and wrapping paper films.

1.5 Distinguishing method: Pull it apart after burning it with fire. The silk is flat and not long.

2 Random copolymerized polypropylene (PP-R)

2.1 It is obtained by the copolymerization of propylene monomer and a small amount of ethylene (1-4%) monomer under the action of heating, pressure and catalyst. The ethylene monomer is randomly and randomly distributed in the long chain of propylene. The random addition of ethylene reduces the crystallinity and melting point of the polymer, and improves the performance of the material in terms of impact, long-term hydrostatic pressure resistance, long-term heat and oxygen aging resistance, and pipe processing and molding. PP-R molecular chain structure, ethylene monomer content and other indicators have a direct impact on the long-term thermal stability, mechanical properties and processing properties of the material. The more random the distribution of ethylene monomer in the propylene molecular chain, the more significant the change in the properties of polypropylene.

2.2 Advantages: good overall performance, high strength, high rigidity, good heat resistance, good dimensional stability, excellent low temperature toughness (good flexibility), good transparency, and good gloss.

2.3 Disadvantages: Best performance among PP.

2.4 Uses: extrusion blowing grade, film grade, injection molding grade. Tubes, shrink films, drip bottles, highly transparent containers, transparent household products, disposable syringes, wrapping paper films.

2.5 Identification method: It does not turn black after being ignited, and can pull out a long round wire.

3 Block (impact) copolymerized polypropylene (PP-B)

3.1 The ethylene content is relatively high, generally 7-15%, but the probability of two ethylene monomers and three monomers being connected together in PP-B is very high, indicating that the ethylene monomer only exists in the block and does not combine the PPH The regularity is reduced, so the purpose of improving the performance of PPH melting point, long-term hydrostatic pressure resistance, long-term heat-oxidative aging resistance and pipe processing and molding cannot be achieved.

3.2 Advantages: better impact resistance, and a certain degree of rigidity improves the impact strength.

3.3 Disadvantages: low transparency, low gloss.

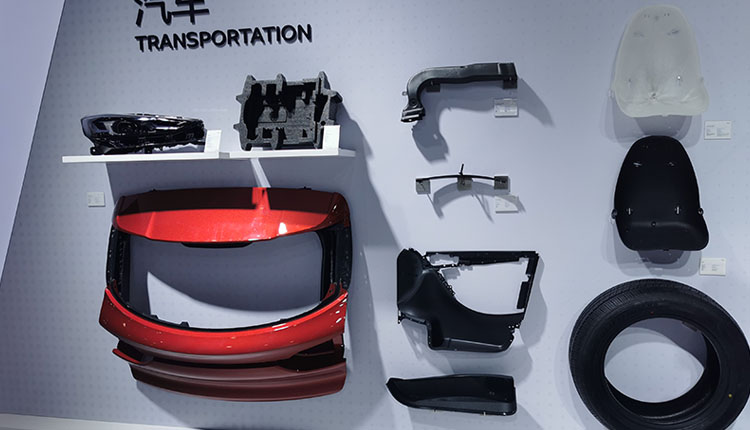

3.4 Uses: Extrusion grade, injection molding grade. Bumpers, thin-walled products, strollers, sports equipment, luggage, paint buckets, battery boxes, thin-walled products.

3.5 Identification method: It does not turn black after being ignited, and can pull out a long round wire.

Shijiazhuang Qibo Chemical Co., Ltd. produces homopolymer PP flame retardant QB-T01 and copolymer PP flame retardant masterbatch QB-PN3, both of which can be used for high-performance copolymer PP flame retardancy.