What is Injection Molding

- Postdate: 2023-03-21

- From: qibochem.com

-

What is Injection Molding

- Postdate: 2023-03-21

- Form: qibochem.com

-

1 Introduction

Injection molding is a method of producing shapes for industrial products. Products usually use rubber injection molding and plastic injection molding. Injection molding can also be divided into injection molding molding method and die casting method.

Injection molding machine (referred to as injection machine or injection molding machine) is the main molding equipment for making thermoplastic or thermosetting materials into various shapes of plastic products using plastic molding molds. Injection molding is realized through injection molding machines and molds.

2 Main types

2.1 Rubber injection molding: Rubber injection molding is a production method that injects rubber directly from the barrel into the model for vulcanization. The advantages of rubber injection molding are: although it is an intermittent operation, the molding cycle is short, the production efficiency is high, the blank preparation process is canceled, the labor intensity is small, and the product quality is excellent.

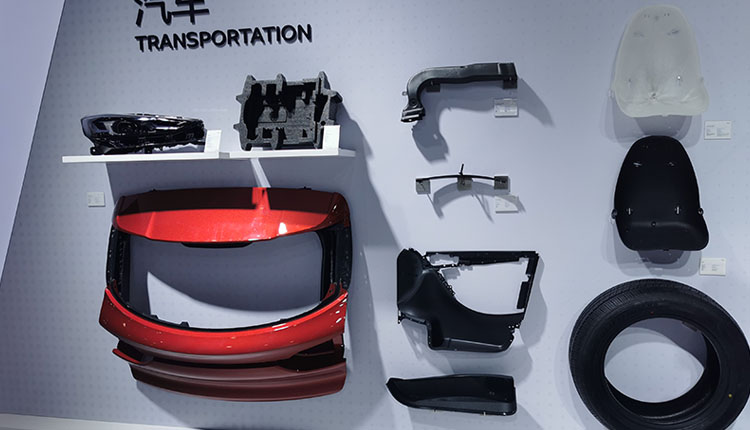

2.2 Plastic injection molding: Plastic injection molding is a method of plastic products. The molten plastic is injected into the mold of the plastic product under pressure, and cooled and formed to obtain various plastic parts. There are mechanical injection molding machines specially designed for injection molding. The most commonly used plastics are polyethylene, polypropylene, ABS, PA, polystyrene, etc.

2.3 Molding injection molding: The resulting shape is often the final product, and no other processing is required before installation or use as a final product. Many details, such as bosses, ribs, threads, can be formed in a single injection molding operation.

3 Injection molding materials commonly used in injection molding

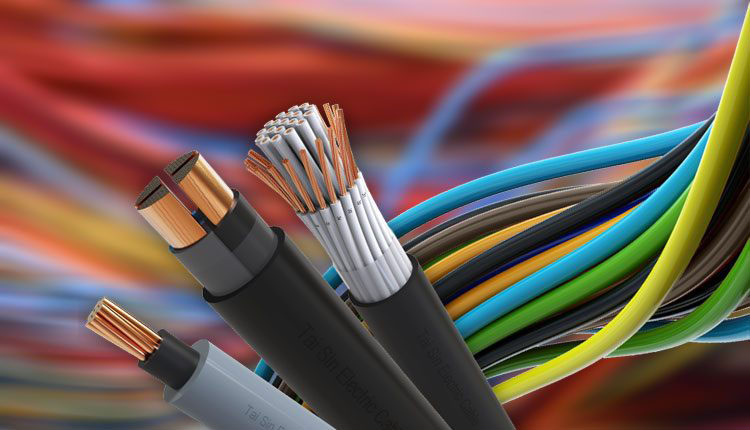

Injection molding materials include PE, PP, PS, etc., which are thermoplastic and suitable for thermal injection molding.

PE: PE is also called polyethylene. It is one of the more commonly used polymer materials in daily life. It is widely used in the manufacture of plastic bags, plastic films, and milk barrels.

PP: polypropylene, has high crystallinity and regular structure, so it has excellent mechanical properties. The value of the mechanical properties of polypropylene is higher than that of polyethylene, but it is still a low variety in plastic materials, and its tensile strength can only reach 30 MPa or a slightly higher level. Polypropylene with a larger isotactic index has higher tensile strength, but as the isotactic index increases, the impact strength of the material decreases, but it does not change after falling to a certain value.

Shijiazhuang Qibo Chemical Co., Ltd. has homopolymerized and copolymerized flame-retardant masterbatches suitable for direct injection molding, such as high-efficiency PP flame-retardant masterbatches QB-PN1, QB-PN2, general-purpose V0 flame-retardant masterbatches and copolymerized PP flame-retardant Masterbatch QB-PN3, etc.