What is EPS

- Postdate: 2023-05-06

- From: qibochem.com

-

What is EPS

- Postdate: 2023-05-06

- Form: qibochem.com

-

Introduction

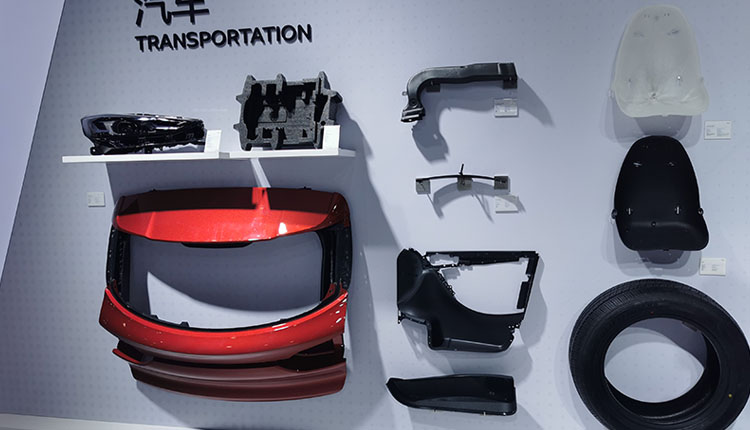

Expanded polystyrene, also known as expandable polystyrene (EPS), has low relative density (1.05g/cm3), low thermal conductivity, low water absorption, shock and vibration resistance, heat insulation, sound insulation, With the advantages of moisture resistance, vibration reduction and excellent dielectric properties, it is widely used in shockproof packaging materials for mechanical equipment, instruments, household appliances, handicrafts and other fragile and valuable products, as well as fast food packaging.

Preparation Process

There are two main preparation techniques for EPS particles: 1. One-step impregnation process (referred to as one-step method) is to mix styrene monomer, initiator, dispersant, water, and foaming agent (common foaming agents include pentane and butane). It is added into the reaction kettle together with other additives, and after polymerization, resin particles containing foaming agent are obtained.  After washing, centrifugal separation and drying, expandable polystyrene beads are obtained; 2. Two-step impregnation process (referred to as two-step impregnation process) Step method) is to first polymerize styrene monomer into polystyrene beads with a certain particle size, then classify and sieve, then add water, emulsifier, foaming agent and other additives in the reaction kettle, heat and impregnate to obtain Expandable polystyrene bead products, this method is also called post-dipping method. The one-step process is characterized by simple process, low investment cost, and is superior to the two-step process in terms of reducing consumption and saving energy. At present, the process of producing expandable polystyrene in foreign countries is mainly one-step method and suspension method.

After washing, centrifugal separation and drying, expandable polystyrene beads are obtained; 2. Two-step impregnation process (referred to as two-step impregnation process) Step method) is to first polymerize styrene monomer into polystyrene beads with a certain particle size, then classify and sieve, then add water, emulsifier, foaming agent and other additives in the reaction kettle, heat and impregnate to obtain Expandable polystyrene bead products, this method is also called post-dipping method. The one-step process is characterized by simple process, low investment cost, and is superior to the two-step process in terms of reducing consumption and saving energy. At present, the process of producing expandable polystyrene in foreign countries is mainly one-step method and suspension method.

Forming Process

There are also two main processes for EPS molding: 1. One-step extrusion route, which is directly hot-extruded after EPS particles are foamed. This method is mostly used to manufacture sheets and films; 2. Molding route. Air (or water vapor) at 100°C is pre-foamed 30-50 times, and then left for 24 hours to mature, and then the matured pre-foamed material is placed in a mold made of aluminum or castings, and 115-120 The air (or water vapor) at ℃ is heated, and while the material expands, the surfaces of the particles fuse with each other to form a foam plastic part by the action of heat.

Storage and Transportation

EPS products are generally safe and non-toxic, but raw materials in different states during processing have certain dangers. Polystyrene powder can irritate the respiratory tract and skin. EPS particles in storage emit vapors of pentane, which is extremely flammable and can form explosive mixtures with air. Heating polystyrene-based polymers may release styrene monomer, which is a hazardous substance.

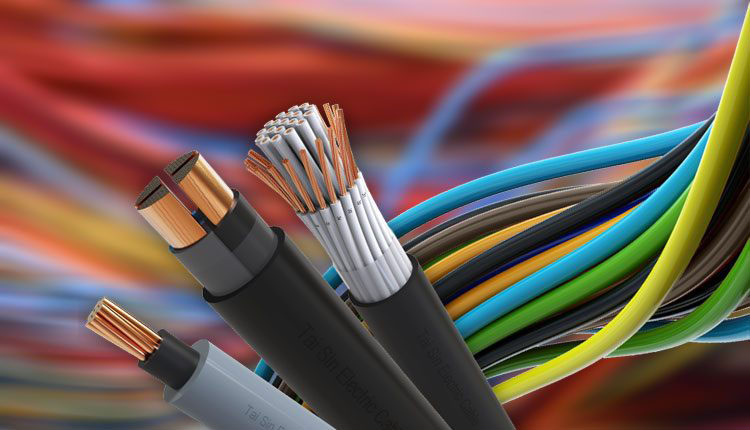

Shijiazhuang Qibo Chemical Co., Ltd. specializes in the production of PP, PC, PE, PA, PET, ABS, PVC, XPS, EPP, EPE, PEEK, PPR, PPA, PEI, PAI, LDPE, HDPE, DBDPE, DBDPO, BDDP, TBPC, ATO, TBBP flame retardants for 16 years in China.