How to choose the acceptable flame retardant for polypropylene nonwovens?

- Postdate: 2022-10-12

- From: qibochem.com

-

How to choose the acceptable flame retardant for polypropylene nonwovens?

- Postdate: 2022-10-12

- Form: qibochem.com

-

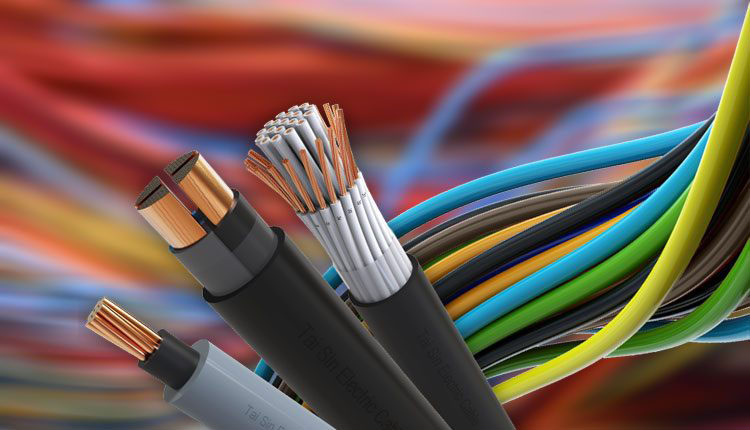

Nonwoven fabrics used in more and more applications with the requirement of flame retardancy. Without flame retardant additives, nonwoven fabric easily lead the risk of fire happened in many cases, especially in industry area. In order to reduce the heavy cost after fire taken, add with flame retardant additive become the best way lower down the heavy losses.

Flame retardant nonwoven fabric can be achived in two ways: additive- mix together with carries of polypropylene and topical-coating FR chemistry on the fabric. With our developed FR masterbaches, additive FR types are useful for thermoplastics.

How to choose the acceptable FR for polypropylene nonwoven fabric, think the bellow commendation can be your references:

1. No adversely affect the natural color of final fiber products.

2. Non-blocking during process of fiber .

3. Non-smoking during fiber production.

4. High decomposition temperature, excellent thermal and light stability.

5. No adverse on UV durability.

During the processing of flame retardant with carrier polypropylene, some point should be considered:

1. Good thermal stability, lower than 260℃(the normal PP processing temperature)

2. Good compatibility with PP, NO migration of the additives,

3. Minimize the effect of fiber properties.

Qibochem not only supply the flame retardants, more we focus that the reliable solution for each of our customer.