Flame Retardant Modification of Nylon Materials

- Postdate: 2023-03-17

- From: qibochem.com

-

Flame Retardant Modification of Nylon Materials

- Postdate: 2023-03-17

- Form: qibochem.com

-

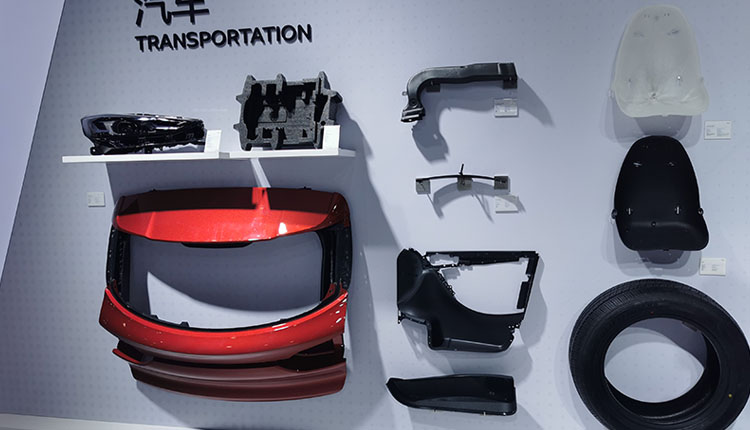

Nylon has excellent performance and is widely used. Unmodified nylon has poor flame retardancy, vertical combustion can only reach UL94 V2 level, oxygen index is about 24%, and drips during combustion, which is a flammable material, which is very easy to cause damage during use. fire. Therefore, the flame retardant modification of nylon has become a common concern and research topic in the academic and industrial circles. At present, the flame retardant modification of nylon materials is usually divided into halogen-containing flame retardant modification and halogen-free flame retardant modification.

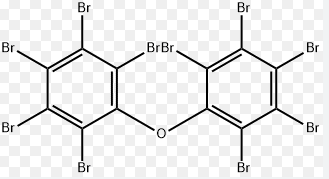

1 Halogenated flame retardant system

One of the most widely used abroad is brominated styrene polymer, which has extremely superior thermal stability, and because it is melt-mixable with nylon, it has good fluidity during processing. In addition, the flame-retardant nylon prepared with it also has superior electrical properties and better physical and mechanical properties. The limitation of this flame retardant is that it has poor light stability and is not fully compatible with nylon. In addition, its cost is higher than that of decabromodiphenyl ether, which is widely used in China.

The most widely used flame retardant in China is decabromodiphenyl ether. Due to its high bromine content, it has high flame retardant efficiency for nylon and is the most economical flame retardant. However, because it is a filler type flame retardant, it has a great negative impact on the processing fluidity and the physical and mechanical properties of the product. In addition, its thermal stability and light stability are also poor.

So far, the vast majority of flame-retardant products related to nylon are based on halogen-containing compounds. The dense smoke, toxicity, and corrosive gases generated during flame-retardants have caused secondary disasters in production, application, and the environment. Although this kind of flame retardant plays an important role in the flame retardant arena, people are trying to find a substitute for this kind of flame retardant, that is, a halogen-free flame retardant.

2 Halogen-free flame retardant system

2.1 Phosphorus flame retardant.The phosphorus-based flame retardants suitable for nylon mainly include ammonium polyphosphate (APP) and red phosphorus.

2.1.1 Ammonium polyphosphate (APP)

Ammonium polyphosphate (APP) participates in the thermal degradation process of nylon by lowering the degradation temperature of nylon and changing the composition of the final gas phase product. At the same time, a honeycomb carbonized covering layer is formed on the polymer matrix to block the heat and material transfer at the two-phase interface. Played the role of protecting the matrix. Due to the tendency of charring to flow, the substrate under the charcoal layer will be exposed, increasing the risk of burning. Add some inorganic additives, such as talc (Talc), MnO2, ZnCO3, CaCO3, Fe2O3, FeO, Al(OH)3, etc., to increase the flame retardant effect. Adding one of the above additives (1.5% to 3.0%) to nylon 6 with an APP content of 20% can increase the LOI value to 35% to 47%, reaching the V0 level.

2.2.2 Red phosphorus

The advantage of red phosphorus is that it has a high content of available phosphorus and produces more phosphoric acid than other phosphorus-containing compounds during combustion. When reaching the same flame retardant level, the amount of red phosphorus added is lower than other flame retardants, so that nylon can better maintain its own mechanical properties. But the main disadvantages of red phosphorus as a flame retardant are its red color, flammability and formation of highly toxic phosphine by reaction with water. Generally only used in nylon 6. Microencapsulating or masterbatching ordinary red phosphorus can avoid its disadvantages.

2.2 Nitrogen flame retardant

Nitrogen-based flame retardants have low toxicity, no corrosion, heat resistance, UV resistance, good flame retardant efficiency and low price. The disadvantage is that it is difficult to process flame-retardant plastics and has poor dispersion in the substrate. Nitrogen-based flame retardants suitable for nylon mainly include MCA (melamine cyanurate), MPP (melamine polyphosphate) and the like. Regarding its flame retardant mechanism, on the one hand, it is the physical flame retardant method of "sublimation heat absorption", that is, the "sublimation heat absorption" of the flame retardant reduces the surface temperature of the polymer material and isolates the air to achieve the purpose of flame retardancy. On the one hand, in the condensation, the flame retardant and nylon catalyze the direct carbonization expansion mechanism. They have good flame retardant efficiency, but poor thermal stability, and the products have poor electrical properties in humid environments due to easy moisture absorption.

3 Selection principles of flame retardants

In the manufacturing process of flame retardant nylon, the selection of flame retardants is mainly considered from the aspects of flame retardant efficiency, product performance, toxicity, etc. and coloring performance requirements. According to the requirements of use, it is very important to determine the type and dosage of flame retardant, the choice of additives and the process conditions. The following principles should be followed:

① Good flame retardant effect, less dosage, good compatibility with nylon;

② The decomposition temperature is high, and it does not decompose at the processing temperature of nylon;

③ Excellent durability, no obvious appearance migration;

④It has little influence on the mechanical and electrical properties of the material, and has little corrosion on the equipment;

⑤ Non-toxic, harmless and pollution-free, cheap.

Shijiazhuang Qibo Chemical Co.,Ltd. specializes in the production of PP,PC,PE,PA,PET,ABS,PVC flame retardants for 16 years in China.We have PA66 GF30 flame retardant,PA66 GF30 flame retardant masterbatch,PA66 flame retardant and PA66 flame retardant masterbatch.