EVA Film - a Thermosetting Adhesive Film

- Postdate: 2023-05-26

- From: qibochem.com

-

EVA Film - a Thermosetting Adhesive Film

- Postdate: 2023-05-26

- Form: qibochem.com

-

Introduction

EVA (Polyethylene vinylacetate, the abbreviation of polyethylene-polyvinyl acetate copolymer). It is a thermosetting adhesive film for placing between laminated glass. Due to the superiority of EVA film in terms of adhesion, durability, and optical properties, it is more and more widely used in current components and various optical products.

Advantages of the product

1. High transparency and high adhesion can be applied to various interfaces, including glass, metal and plastics such as PET.

2. Good durability can resist high temperature, moisture, ultraviolet rays and so on.

3. Easy to store. Stored at room temperature, the adhesion of EVA is not affected by humidity and water-absorbent films.

4. Compared with PVB, it has stronger sound insulation effect, especially high frequency sound effect.

5. Low melting point, easy to flow, suitable for laminating process of various glass, such as embossed glass, tempered glass, curved glass and so on.

Applications

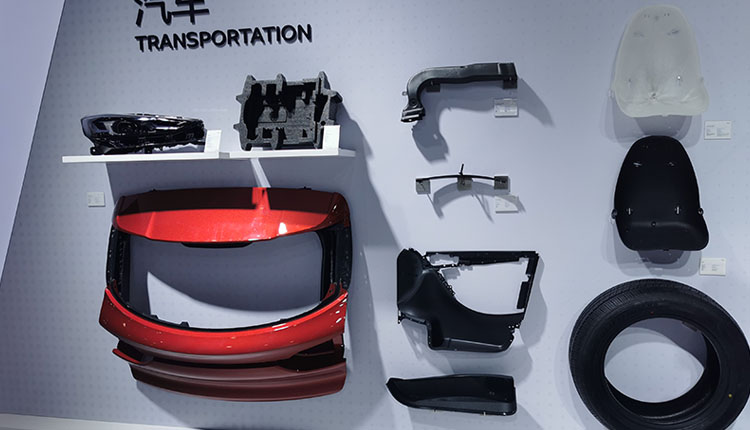

EVA is an extremely common material, and it is a common midsole material in daily life. The finished product is soft, shockproof, non-slip, and compressive, such as common EVA slippers, cotton shoes, EVA mobile phone cases, EVA ipad cases, etc.

Terms and Conditions

1. Curing conditions: for fast-curing adhesive films, heat to 135-140°C and keep the temperature constant for 15-20 minutes; for conventional adhesive films, heat to 145°C and hold the temperature for 30 minutes.

2. Light transmittance: greater than 90%.

3. Degree of cross-linking: more than 70% for fast-curing adhesive films, and greater than 75% for conventional adhesive films.

4. Peel strength: glass/adhesive film is greater than 30N/cm, TPT/adhesive film is greater than 20N/cm.

5. Temperature resistance: high temperature 85°C, low temperature -40°C, no thermal expansion and contraction, good dimensional stability.

6. Anti-ultraviolet aging performance: long-term ultraviolet radiation will not crack or age.

Precautions

During use, pay attention to moisture-proof and dust-proof, and avoid contact with colored objects; do not expose the whole roll of film without the outer packaging to the air; if the film that has been cut into slices cannot be used up in one day, cover it tightly . If the EVA film absorbs moisture, it will affect the adhesion to the glass; if it is vacuumed, it will affect the light transmittance; if it is in contact with colored or unclean objects, the EVA film is easily polluted due to its strong adsorption capacity.

Shijiazhuang Qibo Chemical Co., Ltd.Our company specializes in the production of PP, PC, PE, PA,PET, ABS, PVC flame retardants for 16 years in China.Our company's partners include Haier, Samsung, YUTONG and BYD Auto, etc.