Brominated Flame Retardants Selection

- Postdate: 2023-04-12

- From: qibochem.com

-

Brominated Flame Retardants Selection

- Postdate: 2023-04-12

- Form: qibochem.com

-

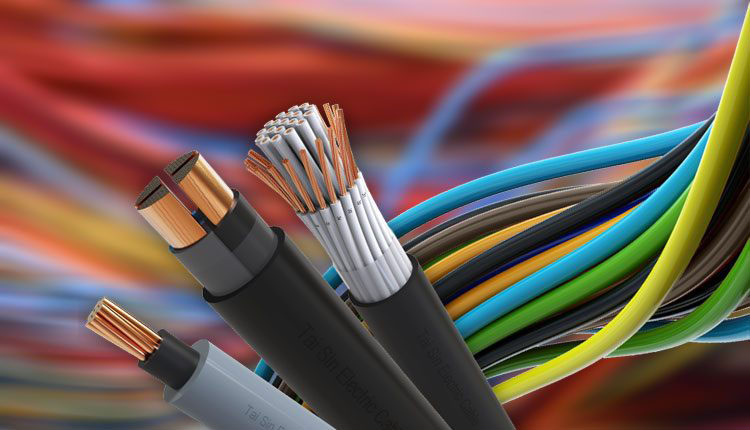

Flame retardant selection depends on your application and the specific flame retardant standards and regulations that you have to meet. There are a number of others issues which must be considered when selecting the best FR system for a given use.

Following are the factors which may impact brominated flame retardants selection:

1 Bromine Type and Content

In order to be effective, the selected brominated flame retardant must decompose when the polymer burns but remain stable during polymer processing; this in turn dictates the type of bromine in the FR. It must also have sufficient bromine content to allow you to obtain the FR performance you require while not adversely effecting physical properties and overall system cost due to high loadings.

2 Thermal Stability

The selected brominated flame retardant must remain stable during compounding and injection molding. Decomposition during these steps can lead to color formation, degradation of the polymer and equipment corrosion. Hence selection of the correct FR along with any heat stabilizers and synergist that may be required is extremely important.

3 Aging Characteristics

Your resin system may have to withstand various factors that can cause premature degradation of properties and color formation. Factors like UV stability, thermal stability and migration will dictate the best flame retardant to use in your system along with any stabilizers required.

4 Processing Characteristics

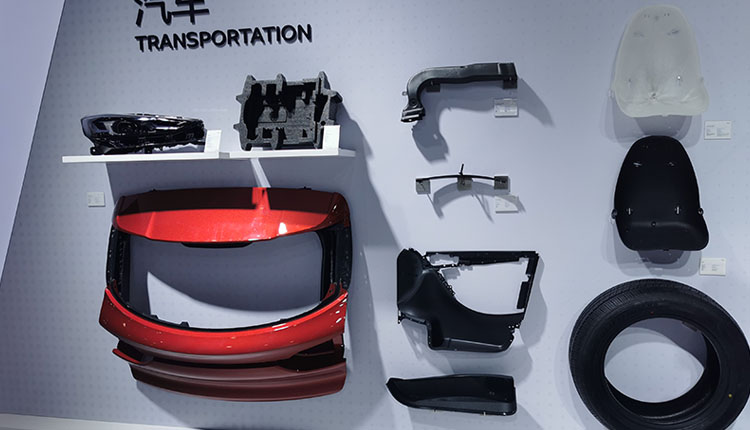

Depending on your processing temperature certain FR's are melt blendable while others act as fillers. This can affect your processing and final physical properties.

5 Standard to be met

Flame retardants' selection will depend heavily on your resin system you have chosen and the standards to be met.

6 Cost in use

The overall cost of the entire package needs to be taken into account which is not just a function of the cost of the brominated flame retardant but its required loading and what other additives are required to be used with it, in order to obtain a viable system.

7 Environmental

The use of brominated flame retardant induces specific environmental constraints. One of the key topics is to reduce toxic hazards at each step of your production process (from manufacturing to end-use and disposal).

8 Non-Blooming

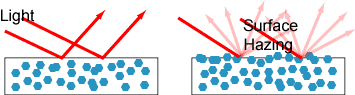

Blooming is very slow process where the flame retardant migrates to the surface of the plastic resulting in a hazy surface, which often has a bronze like appearance.

This effect is particularly undesirable for parts that also have an aesthetic function such as enclosures and housings. For this reason, blooming is an mportant criterion to consider for some applications.

Generally, blooming depends on the compatibility of the FR with the polymer additive as well as the FR's molecular weight. The higher the compatibility and the molecular weight, the lower the blooming.

9 UV Stability

In many applications, the flame retardant resin may have to withstand various conditions that can cause premature degradation of properties and discoloration.

For this reason selecting the right brominated flame retardant is critical for UV stable applications and in particular for outdoor applications.

Shijiazhuang Qibo Chemical Co., Ltd. specializes in the production of PP, PC, PE, PA,PET, ABS, PVC flame retardants for 16 years in China, we have Halogenated and Halogen-free flame retardant.

Halogenated: T01 T02 PN1 PN2 PN3 P01 P03 P02

Halogen-free: T03 T04 PN4 PN5 B01 B03 (phosphorus-nitrogen system does not contain halogen)