Brominated Flame Retardant

- Postdate: 2023-04-06

- From: qibochem.com

-

Brominated Flame Retardant

- Postdate: 2023-04-06

- Form: qibochem.com

-

Brominated flame retardants (BFR brominated flame retardants) are a general term for a group of organic compounds containing bromine. One of the chemical flame retardants. However, the European Union has restricted the use of some brominated flame retardants.

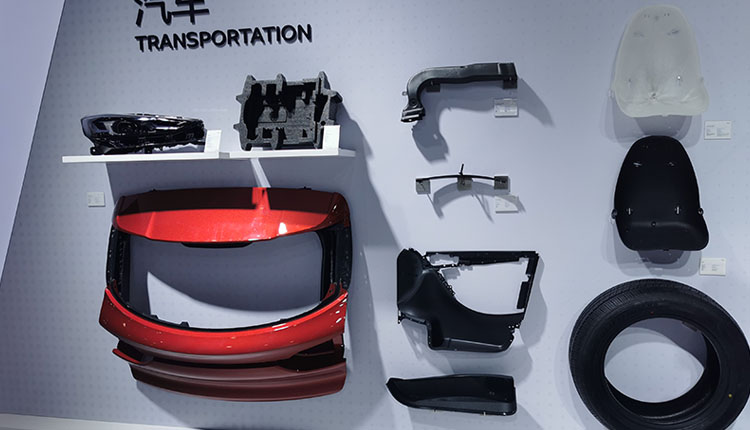

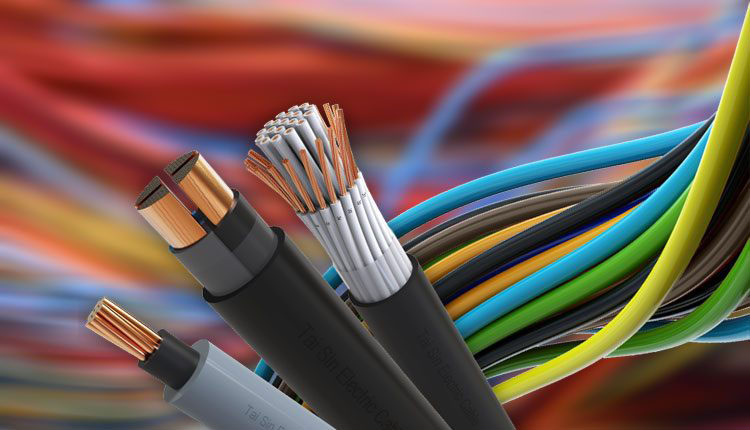

Greenpeace is also calling for a ban on the use of brominated flame retardants in its regular Green Electronics Business Review. Brominated flame retardants can inhibit the combustion of organic compounds and are commonly used in electronic products, clothing and furniture to reduce the flammability of products. About 2.5 million tons of brominated flame retardants are used in polymers each year, of which the annual use of PBDE alone exceeds 40,000 metric tons. In 1999, about 34,000 metric tons of PBBs were used in North America, the most in the world. However, many of the flame retardant-containing products produced in North America are sold to the global market. The electronics industry is the largest user of brominated flame retardants. Taking computers as an example, brominated flame retardants are used in the following parts of computers: printed circuit boards, parts (such as connectors), plastic casings and cables. Brominated flame retardants are also used in many products, including plastic casings for televisions, carpets, paint, sofa upholstery, and kitchen appliances.

The fire prevention effect of brominated flame retardants is extremely good, and its application level is quite extensive. In addition to reducing the possibility of fire, brominated flame retardants can also hinder the spread of fire. In the event of a fire, brominated flame retardants can prolong the initial period of the fire, which is often the prime time for people to escape more easily. Indoor fires can easily burn all combustibles in the room by generating enough heat. This is called a flashover and occurs within minutes of starting the fire. Brominated flame retardants can slow down the speed of burning, slow down the appearance of flash fire, so that personnel have more time to escape.

Most brominated flame retardants are fat-soluble and easily accumulate in the human body. The European Union has restricted the use of some brominated flame retardants. Pentabromodiphenyl ether and octabromodiphenyl ether in polybrominated diphenyl ethers have been banned since 2004. In the directive on the restriction of hazardous substances, polybrominated biphenyls and polybrominated diphenyl ethers. The maximum allowable amount of brominated diphenyl ethers is 0.1%.

Most brominated flame retardants will decompose at 200-300°C, which is exactly the decomposition temperature range of polypropylene, so when polypropylene is heated and decomposed, brominated flame retardants also begin to decompose and can capture other Free radicals generated by degradation reactions, thereby delaying or terminating the chain reaction of combustion. At the same time, the released HBr itself is a kind of difficult-to-flammable gas. This gas has a high density and can cover the surface of the material to block the combustible gas on the surface and inhibit the combustion of the material. The main disadvantage of brominated flame retardants is to reduce the anti-ultraviolet stability of the flame-retardant substrate, and generate more smoke, corrosive gases and toxic gases during combustion, which limits its application to a certain extent.

Shijiazhuang Qibo Chemical Co., Ltd. specializes in the production of PP, PC, PE, PA,PET, ABS, PVC flame retardants for 16 years in China, such as polypropylene filament flame retardants, non-woven special color masterbatches, low-odor automobile special flame retardants, Automotive V0 flame retardant masterbatch, high gloss flame retardant and anti-aging flame retardant masterbatch, etc.Our company's partners include Haier, Samsung and BYD Auto, etc.